aRTi-D™ Quality, Quality Control

What is it and how it works?

An integrated solution for real-time detection of defective products and suggestions for improvement with the aim to reduce waste and costs and increase customer satisfaction by minimizing product recalls.

Data collection

▶ Real-time monitoring of product quality.

▶ Secure, web-based access to machine data.

▶ Integration of different measurements from any source (sensors, image, sound, etc.).

▶ Support of multiple types of sensors (analog, 4-20mA, voltage, digital interfaces, etc.).

▶ Pre-processing data locally, to reduce the amount of data transferred to the server/Cloud.

▶ Expandability to meet future needs by adding additional devices.

▶ Increased flexibility: Wired/wireless.

▶ Installation and direct operation (plug n' play).

Indicative Types of Control

▶ Foreign object.

▶ Label paste.

▶ Date/batch code.

▶ Level control.

▶ Bottle cap.

▶ Final packaging.

▶ Crack control.

▶ Material shortage.

▶ Bottle leak detection.

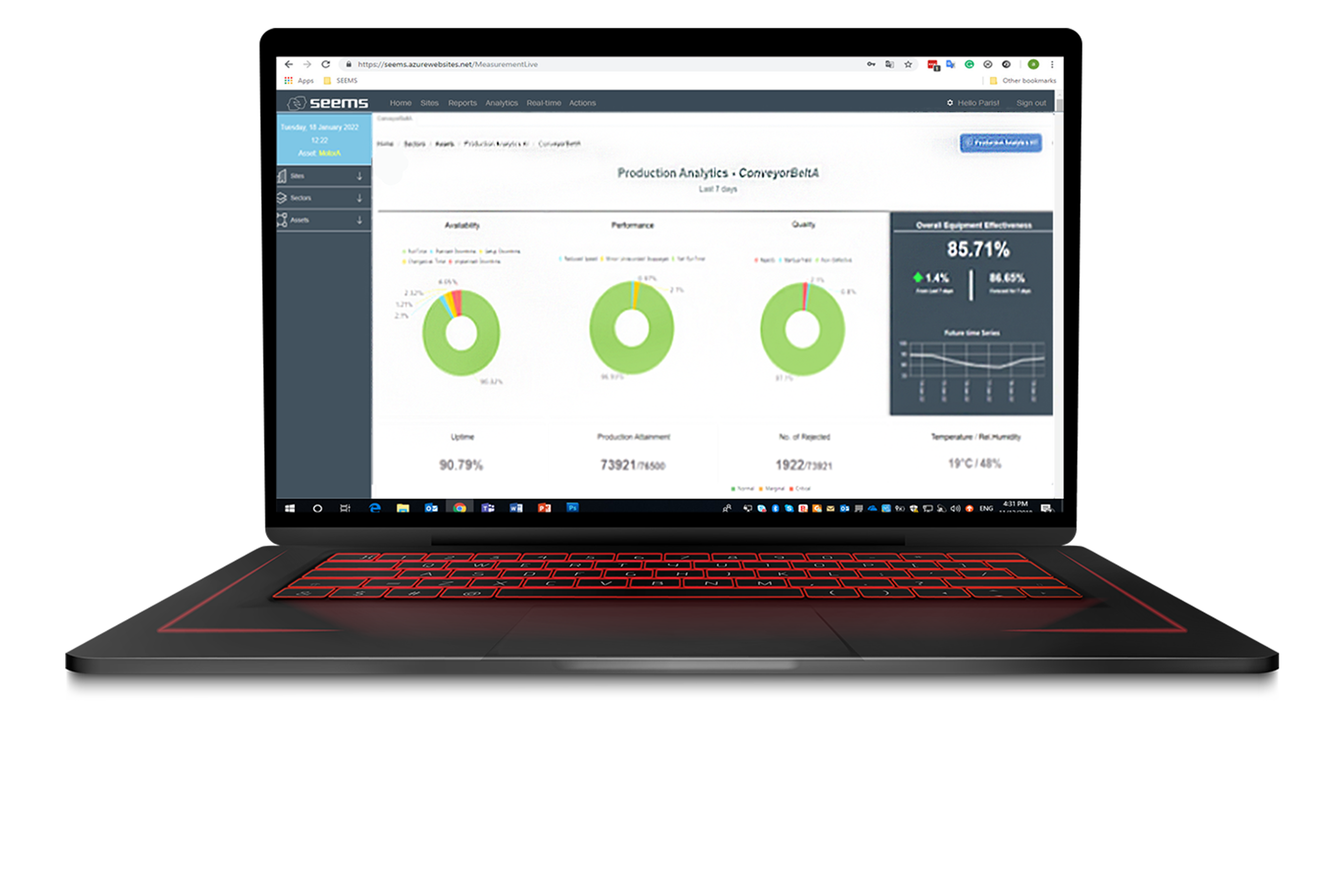

Information Visualization

Counting defective products.

Productivity trends an predictions.

Root-cause analysis of downtimes.

Overall Equipment Effectiveness (OEE).

Defective product tracking.

Suggestions for improvement in real time.

Production Attaintment.

Performance map (heatmap).

Counting of products produced.

Production Analytics based on historical data.

Production line speed.

Historical data.

Benefits

▶ Reduction in product recall costs and lost materials.

▶ Product quality assurance.

▶ Compliance with international regulations.

▶ Increased equipment performance and productivity.

▶ Reduction of operational production costs.

▶ Customer satisfaction and business reputation maintained.

▶ Payback in less than 12 months.