aRTi-D™ Auto,Production Process Automation

▶ Data collection

▶ Real-time monitoring and/or control of production equipment.

▶ Edge-based applications to pre-process data for analysis, predictions, and optimization.

▶ 100% designed and developed by SEEMS. It does not depend on third-party products for data processing.

▶ Integration of different measurements from any source (sensors, image, audio, SCADA, other instruments, etc.).

▶ Support of multiple types of sensors (analog, 4-20mA, voltage, digital interfaces, etc.).

▶ Expandability to meet future needs by adding additional devices.

▶ Increased flexibility: Wired/wireless.

▶ Installation and direct operation (plug n' play).

▶ No training is required.

What is it and how it works?

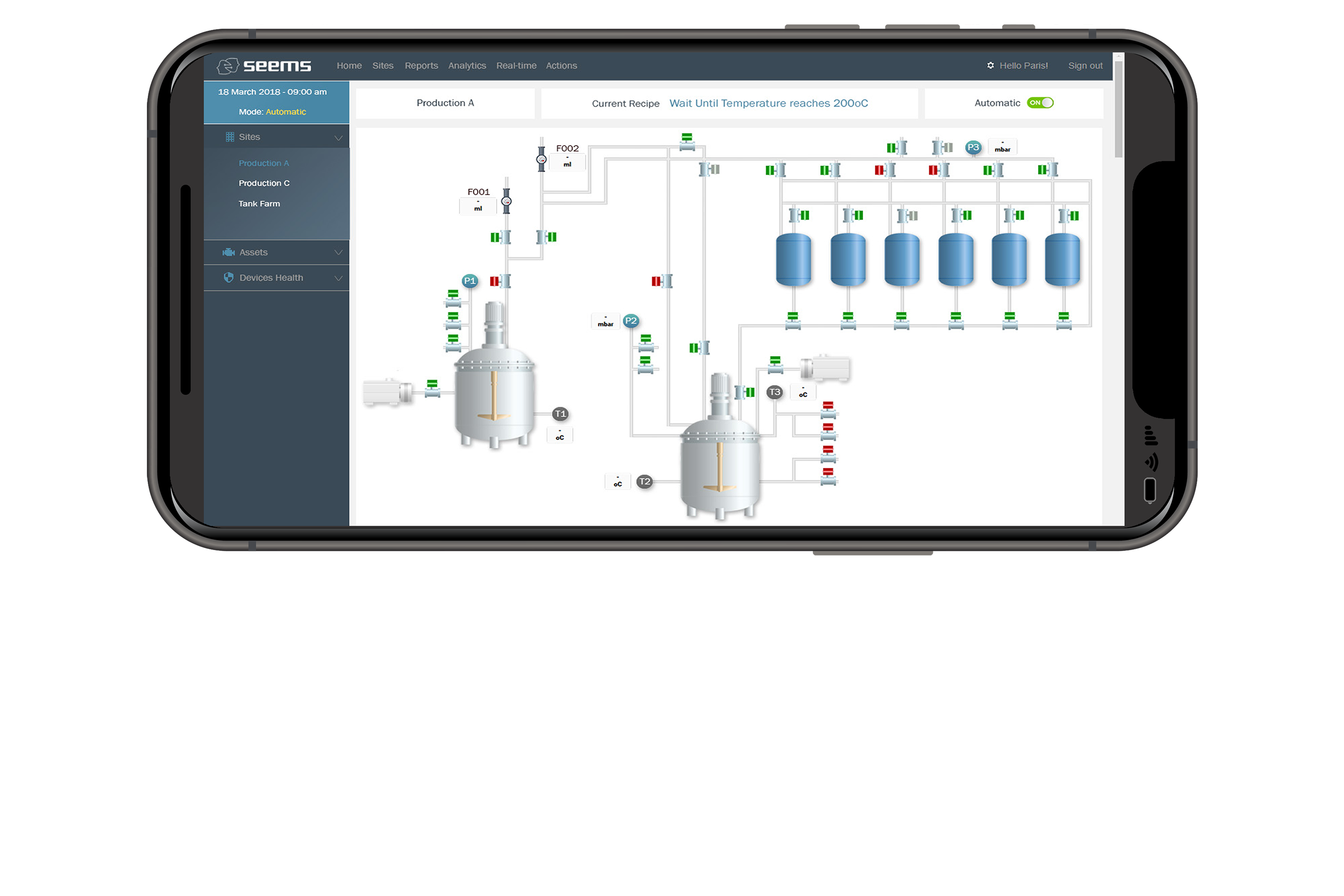

A complete management and control system of all equipment and processes for the management, organization and automated execution of recipes from anywhere inside and outside the company. The automated recipe management solution includes the control of equipment such as reactors, filters, tanks, etc., for the functions of temperature control, pressure control, stirring, liquid transfer, liquid dosing, as well as any other secondary actions required by a production.

Remote Production Monitoring and Control.

Traceability of all actions (Audit trail).

Statistical Reports.

Management and Execution of Recipes.

Role-based security and electronic signatures.

Recipe version control.

▶ Data processing

▶ Information Visualization

Global View

▶ All sites in one map.

▶ Anomaly update by location.

▶ Comparison of producer performance.

Site View

▶ All productions on one screen.

▶ Recipe status by production.

▶ Producer performance comparison.

Production View

▶ Monitoring and control process.

▶ Mode status (Manual/Automatic).

▶ Recipe Status.

▶ Full system audit trail.

▶ Process reports.

▶ Trend graphs.

▶ Anomalies log file.

▶ Measurement log file.

▶ Alarms/Notifications.

Recipe View

▶ Add/modify steps.

▶ Add/modify recipes.

▶ Add/modify parameters.

▶ Execute recipes.

▶ Edit before and during runtime.

▶ Reports.

▶ Alarms/Notifications

Surveillance of Means of Production

Surveillance Sizes

▶ Temperature

▶ Humidity

▶ Vibration

▶ Pressure

▶ Current

▶ Speed

▶ Flow

▶ Dosing

▶ Ultrasound

▶ Image

▶ Gas

Surveillance Points

▶ Valves

▶ Pumps

▶ Generators

▶ Motors

▶ Mixers

▶ Reactors

▶ Agitators

▶ Fans

▶ Compressors

▶ Chillers

▶ Gearboxes

▶ 10% -25% Increase in efficiency and productivity.

▶ 15%-20% faster production.

▶ 100% Traceability.

▶ 25%-30% Increase in asset availability.

▶ 100% Timely and effective decision-making at all levels 24/7