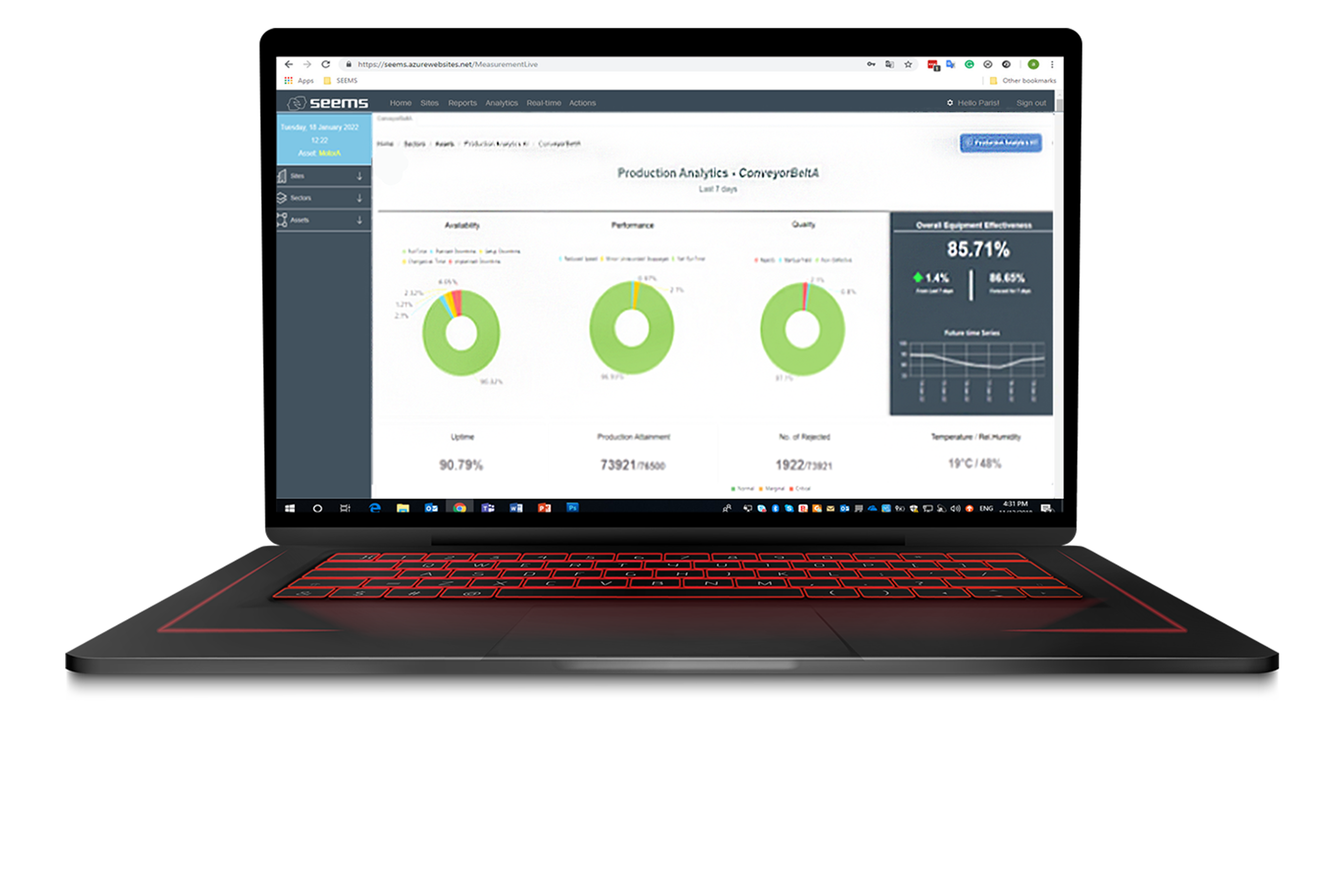

aRTi-D™ OEE, Production Analytics

What is it and how it works?

An integrated solution to minimize lost production times, by identifying and analyzing micro-stops of production assets, with the aim of increasing productivity.

Data collection

▶ Real-time monitoring of machines and facilities.

▶ Secure, web-based access to machine data.

▶ Integration of different measurements from any source (sensors, image, sound, etc.).

▶ Support of multiple types of sensors (analog, 4-20mA, voltage, digital interfaces, etc.).

▶ Pre-processing data locally, to reduce the amount of data transferred to the server/Cloud.

▶ Expandability to meet future needs simply by adding additional devices.

▶ Increased flexibility: Wired/wireless.

▶ Installation and direct operation (plug n' play).

Data processing

Algorithms look for correlations and anomalies so that together with statistical (historical) analysis, they can provide:

▶ diagnosis based on root-cause analysis,

▶ predictions as well as

▶ the economic impact of events.

Information Visualization

Overall Equipment Effectiveness (OEE) & Personnel (OLE).

Production Attainment

Runtime & Downtimes.

Production line speed.

Suggestions for improvement in real time.

Productivity trends and predictions.

Root-Cause analysis of downtimes.

Products counting

Performance map (heatmap).

Production analytics based on product history.

Production runtime.

Counting defective products.

Benefits

▶ Increased equipment performance and productivity

▶ eduction of operational production costs

▶ Reduction of equipment downtime

▶ Reduction of maintenance costs

▶ Increased asset availability

▶ Customer satisfaction and business reputation maintained

▶ Reduction in product recall costs and lost materials

▶Product quality assurance

▶ Compliance with international regulations

▶ Payback in less than 12 months