aRTi-D™ PM, Predictive Maintenance of Industrial Equipment

Data collection

▶ Real-time monitoring and/or control of production assets.

▶ Secure, web-based access to machine data.

▶ Integration of different measurements from any new or existing data source (sensors, image, sound, etc.).

▶ Support multiple types of sensors (analog, 4-20mA, voltage, digital interfaces, etc.).

▶ Edge-based apps to pre-process data for analysis, predictions and optimization.

▶ Expandability to meet future needs simply by adding additional devices.

▶ Increased flexibility: Wired/wireless.

▶ Installation and direct operation (plug n' play).

What is it and how it works?

An integrated solution (Hardware & Software) for the continuous monitoring, anomaly detection & predictive analysis of industrial machinery powered by artificial intelligence and the Internet of Things technologies.

Εκμάθηση της συμπεριφοράς των μηχανών κατά τη λειτουργία.

Systematic detection of anomalies and localization.

Automated prediction of the remaining operating time.

Συνεχής ανάλυση δεδομένων για ανίχνευση της αιτίας.

▶ Data Analysis

Information Visualization

Global View

▶ All sites in one map

▶ Failure probability per site

▶ Site performance comparison

Site View

▶ View all machines on one screen

▶ Machine status

▶ Machine Comparison

▶ Energy consumption

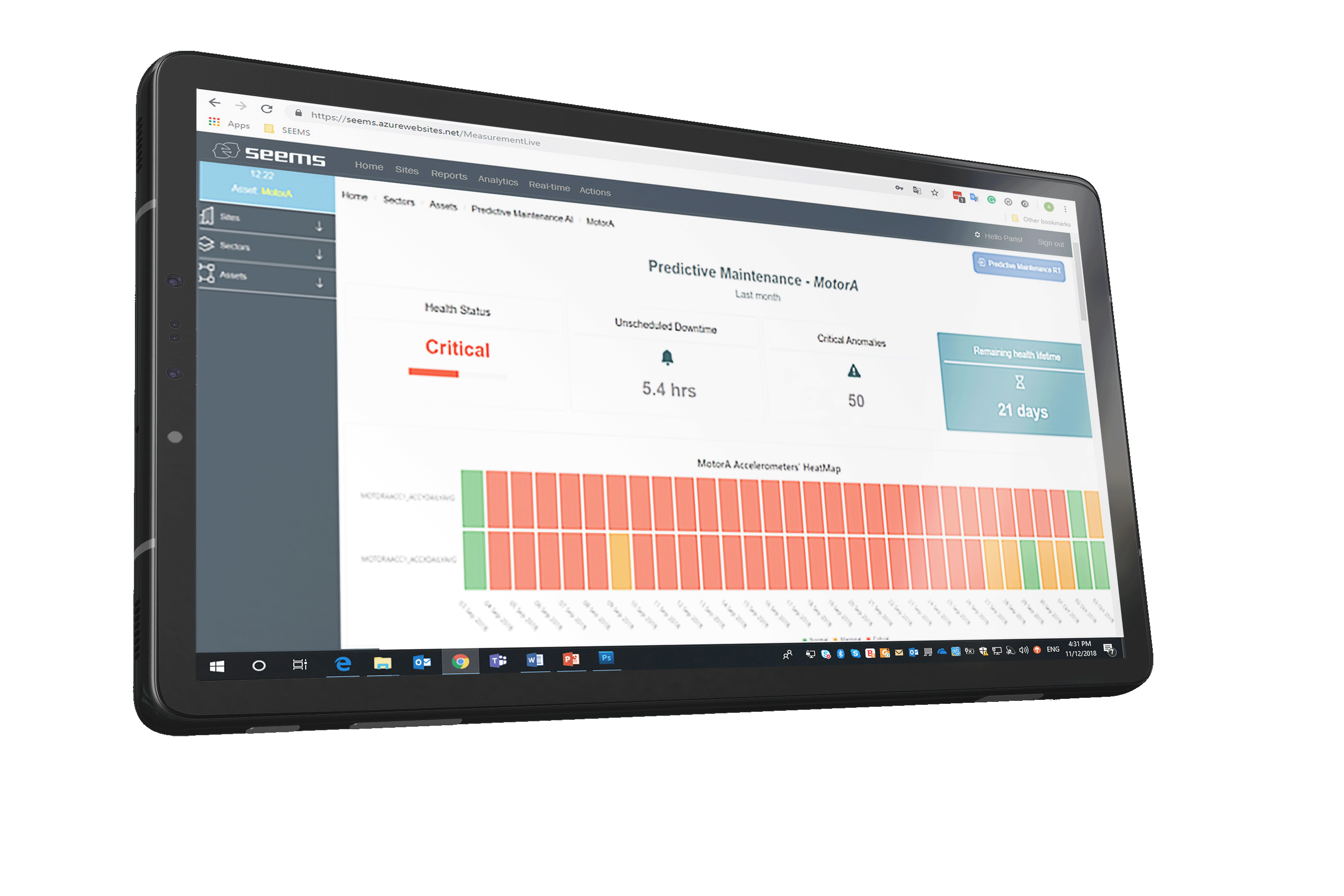

Machine View

▶ Health Status

▶ Anomalies detection

▶ Failure Prediction

▶ Heat Map

▶ Cross-sensor correlations

▶ Maintenance work orders

Sensor View

▶ Root-cause analysis

▶ Anomalies file

▶ Measurements log

▶ Frequency field

▶ RMS Monitoring

▶ Threshold monitoring

Production Asset Monitoring

Parameters

▶ Temperature

▶ Humidity

▶ Vibration

▶ Pressure

▶ Current

▶ Ultrasound

▶ Image

▶ Gas

▶ Fuel Consumption

Points of Interest

▶ Engines

▶ Pumps

▶ Generators

▶ Fans

▶ Compressors

▶ Valves

▶ Refrigerators

▶ Gearboxes

▶ HV/AC

Root-Cause analysis

▶ Imbalance

▶ Belt shaft

▶ Eccentricity

▶ Misalignment (Angular & Parallel)

▶ Looseness

▶ Belt drive problems

▶ Gear defects

▶ Bearing defects

▶ Cavitation

▶ Shaft cracks

▶ Leaks

Benefits

▶ 10%-25% Increase in production and efficiency

▶ 30%-40% Reduction in downtimes

▶ 30%-50% Reduction in maintenance costs

▶ 25%-30% Increase in the asset availability

▶ 100% Timely and effective decision-making at all levels 24/7