aRTi-D™, Indicative case studies

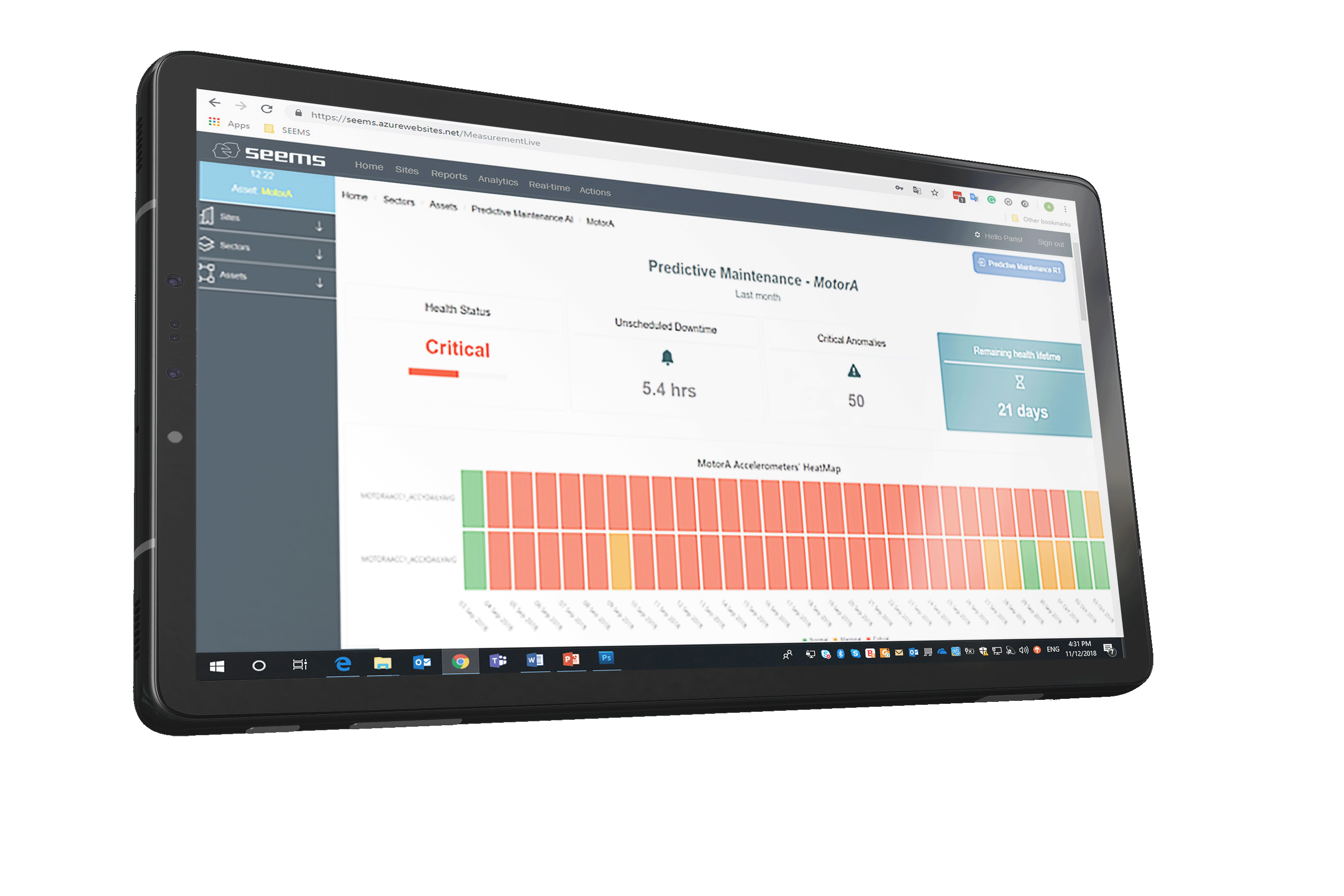

Predictive Maintenance

Result: 28% Reduction of Maintenance Costs

A Greek hydroelectric power company was looking for a solution to monitor the operations of the generator of its Hydroelectric unit, through various sensors, with the aim of predictive maintenance and forecasting of energy production. The monitoring process included functions of collecting, evaluating, processing, storing, and monitoring the various functionally critical generator measurements.

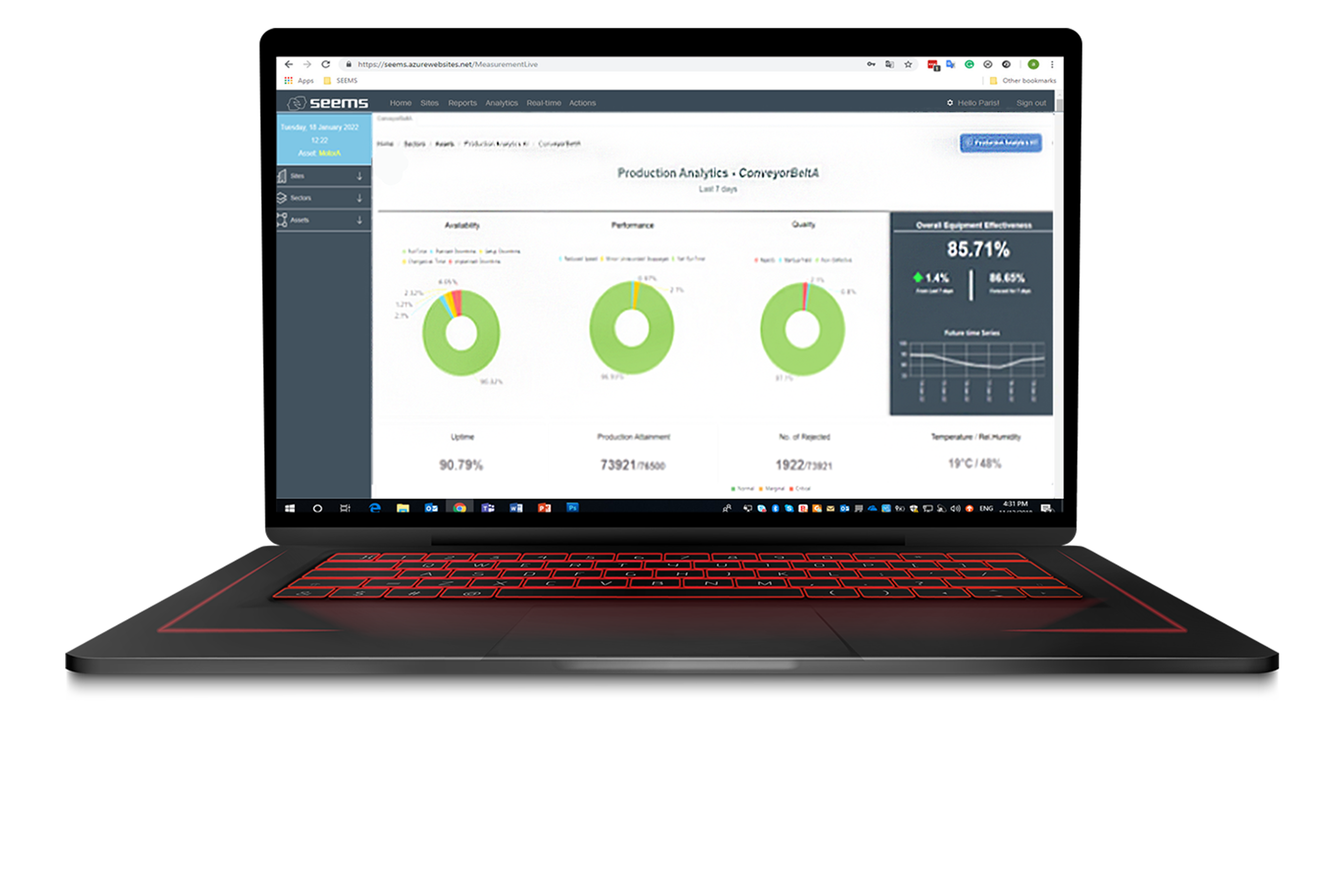

Production Analytics

A Greek plastic manufacturing company was looking for a solution to deal with lost production times, through the analysis of production data. Micro-outages at various points on the production line (repeated and non-repeated) trigger alarms, which cause delays in the production process, with difficulty in determining the exact cause of the problem and a serious impact on the production volume.

Result: 20% increase in productivity

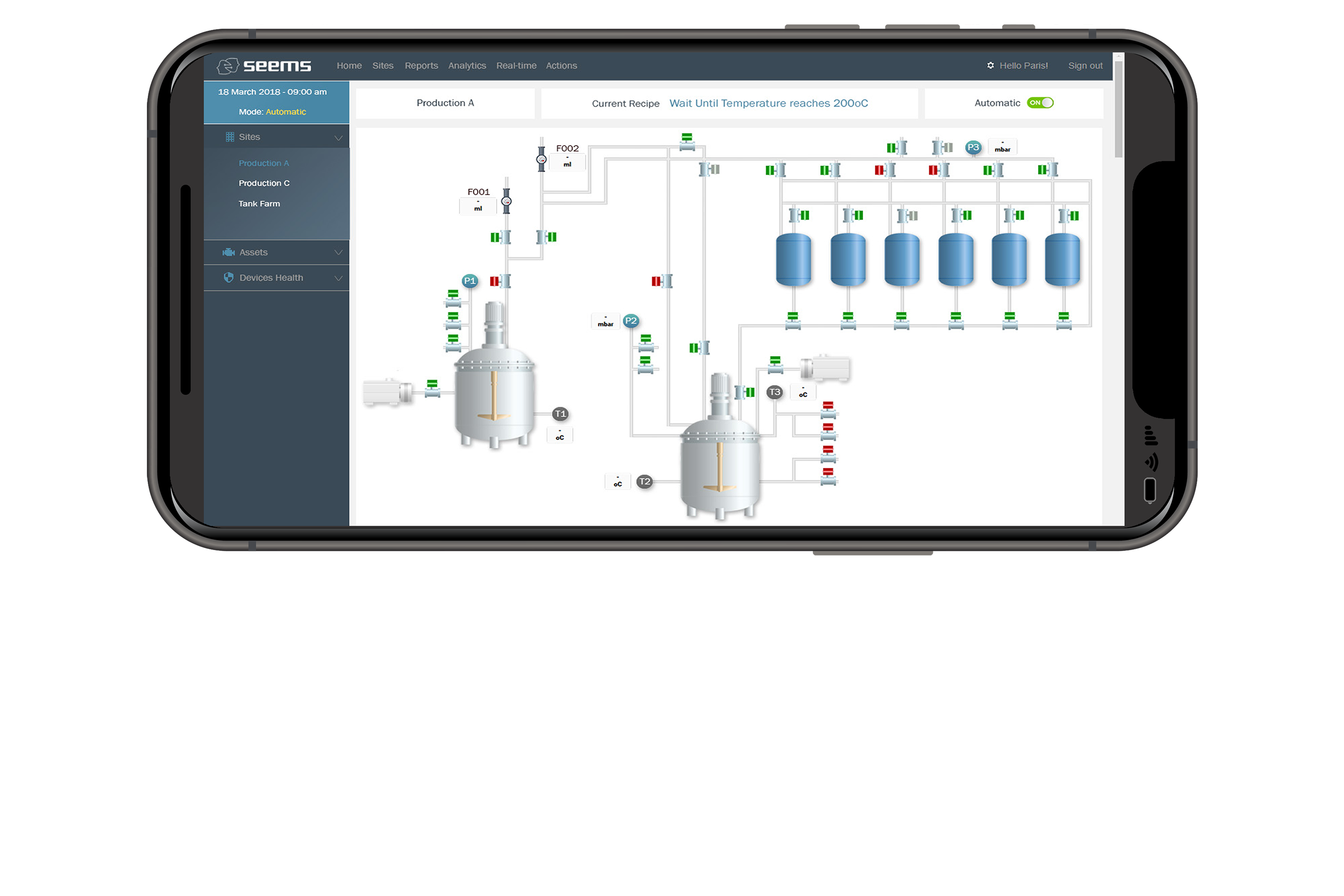

Production Process Automation - Automated Recipe Management

Result: 15% Faster Production

One of the largest suppliers of peptide materials in the world, was seeking to digitize, automate and improve the operation and control of its production. The requirement included monitoring and control of temperature, humidity, pressure, dosage, mixing and controlled transport of fluids for all equipment (reactors, filters, tanks, etc.).